2 1/2 years of work by owner, Jim Llewellyn

All photography by the gifted journalist and creative writer, Doug Crist, MFA

Deck Work

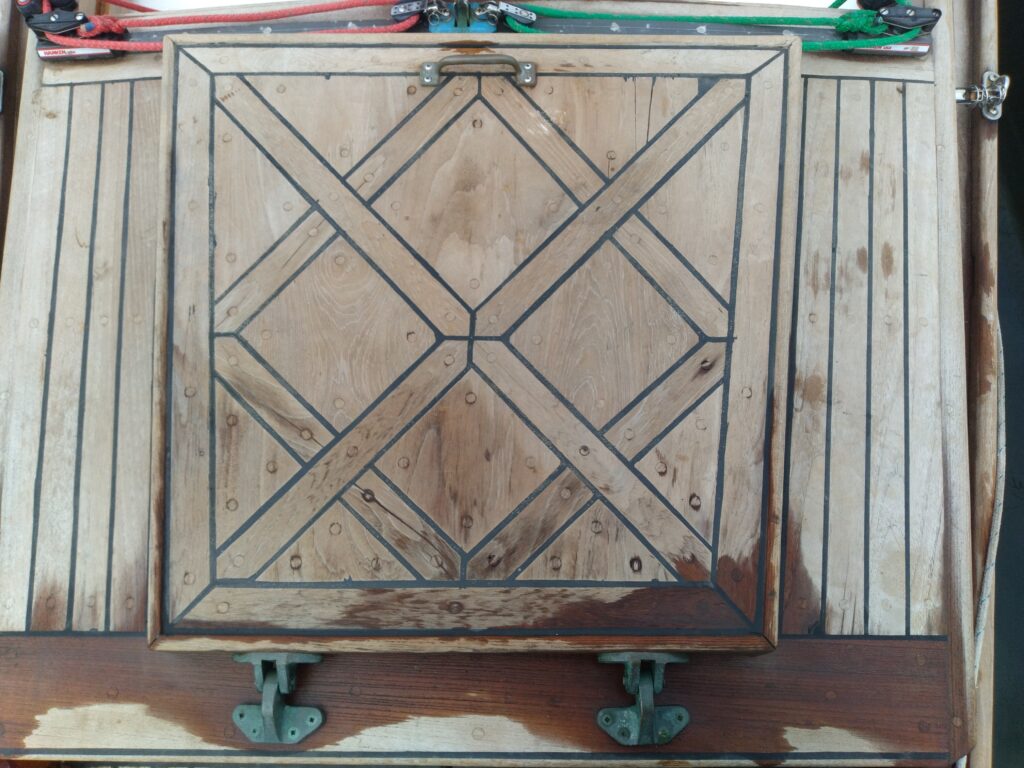

The Teak decks were installed by Jim shortly after buying the boat in 1977. the canvas was shot and Jim wanted a long term replacement. They are 1/4″ x 1.5″ teak strips bedded in epoxy. The black catalyzed polysulphide (known as “thiokol”) in the seams was in need of replacement and Jim decided on West System G-Flex. All control lines are led aft. And all those fittings had to be removed before re-filling the seams.

Early in the refinishing project- everything removed.

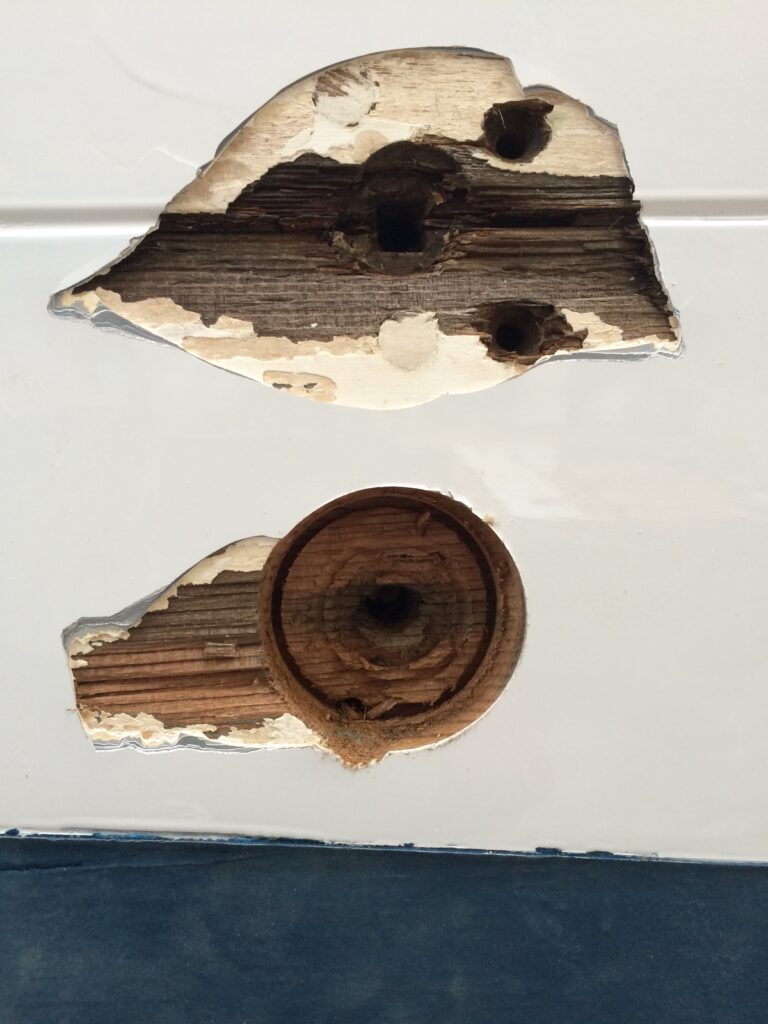

Refastening the hull planks and the chain-plate bolt holes. Much refastening had been done in earlier years when the cockpit and interior was rebuilt and all but two frames were sister-ribbed. This re-fastening involved replacing hundreds of #8 silicon bronze FH screws with #10s. When sister ribs were installed adjacent to the ones through which the chain-plates were bolted new stainless chain-plates were fabricated to span both frames (much more strength against shroud tension when heeled-over). Since the chain-plate bolts were compressing the cedar hull planks Jim custom-made Mahogany “doughnut discs” for better compression resistance.

Hull refinishing

This was the 4th time I repainted the topsides with Awlgrip Matterhorn White and 545 primer. You can see where the rub rail was removed (because the 1 3/4″ wide one was to be replaced with 1 1/2″ wide…more like original).

Details

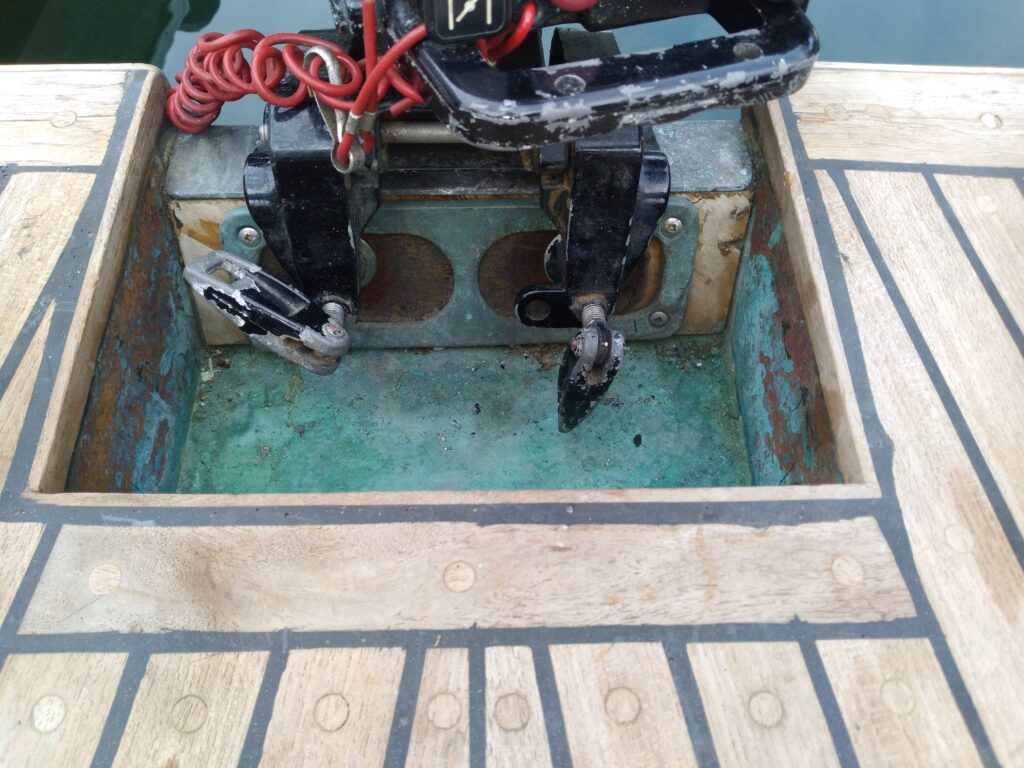

Tiller cap

The rudder, tiller, and mounting channel were replaced early on by Jim (who was building Star boats at the time and knew the process since Blanchard rudders, tillers, etc were identical to those for Stars). Alas, the aluminum was susceptible to wear.

Sister Rib

The last one of more than 32.

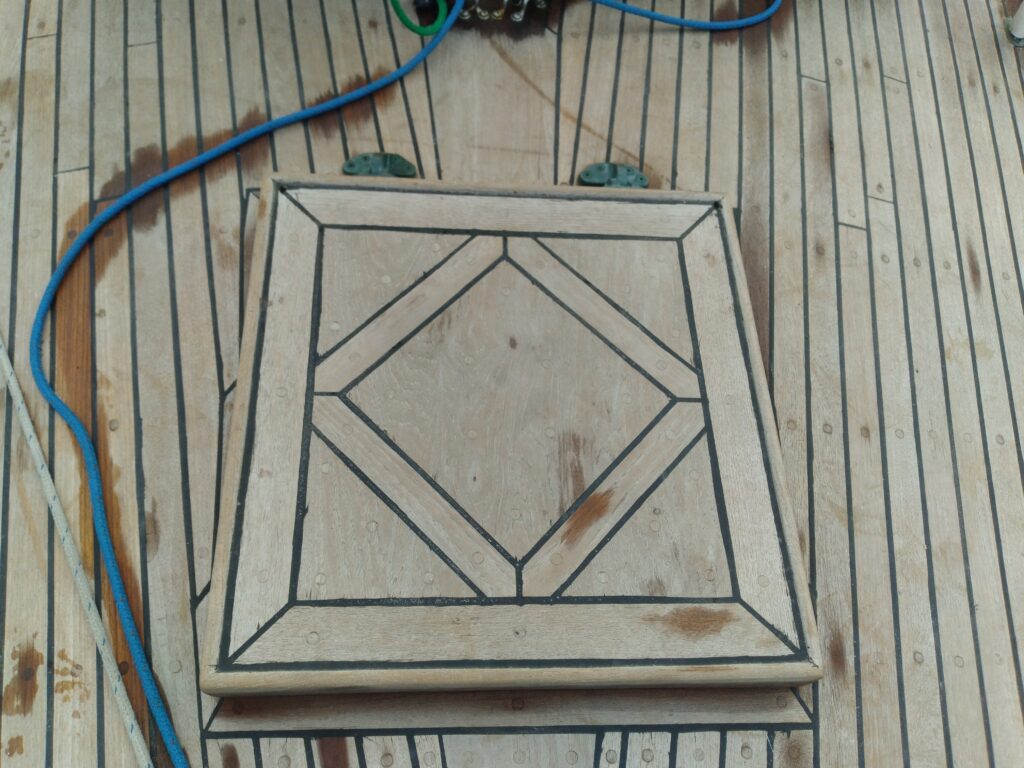

Hatches get refinished

Deck refinishing projects

Replacing the old “Thiokol” catalyzed polysulphide deck seam compound with West System G-Flex (mixed with graphite powder). First came the laborious job of removing all the old Thiokol. Cabin-top edge rails and deck hardware were removed about the same time.

Deck hand rails

I determined that the teak deck handrails I built and installed in the early 80’s were a foot too long and interfered with the the control lines led aft to the cockpit. so I removed them (had to be done anyway to work on the teak deck seams) and carefully shortened them by about 12″ at the aft ends.

Cockpit work

When the cockpit was torn out & rebuilt in 1980 or so the seat tops & faces and cockpit sole were all varnished mahogany plywood. That finish was unsustainable 35 years later so they were re-done in white.

The teak trim at the top & bottom of the seat faces and bottom of bulkheads were re-varnished. And, the cockpit combings got many coats of varnish. The teak caps (not original) on top of the cockpit combings were left to weather naturally.

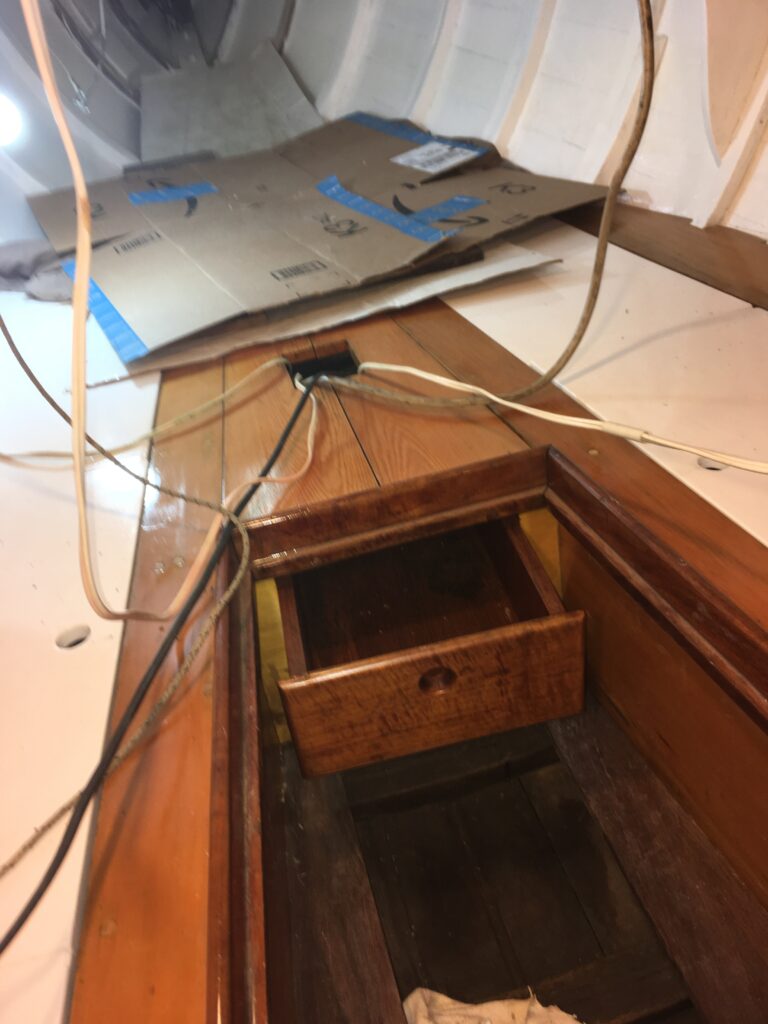

Cabin interior refinishing

Photos are not in order (not good enough with WordPress for that).

The Head

The original Wilcox-Critten “Winner” head was removed, cleaned, sandblasted (with shiny bronze sprayed with clear polyurethane) and rebuilt. “Sealing” strips in the background are Alaskan yellow cedar. They were re-fastened to inside the cabin to the frames just above the berths.

Keel bolt washers

The old galvanized washers were shot so I custom made rectangular stainless steel replacements which would bear on more surface area of the keel timbers. Didn’t want to cut away enough of the one keel timber to allow a rectangular washer-plate so I replaced the old galvanized washers with the largest I could find (probably stainless “fender” washers) with smaller extra thick 316 stainless ones on top of those.

Keel, Rudder, and Bottom Paint

I dropped the keel in the mid 1980s to replace the bolts with stainless (5/8″ machine screws). At the same time I had a flange (extension) brazed onto the back end and drilled new bolt-holes so the keel could be remounted 2.5″ farther forward. I took it to a foundry in Seattle and had four 2″ holes bored through the upper part of the back end of the bulb (to lighten it by 100 pounds). I also ground it down to shiny cast-iron and sheathed it with 3 layers of fiberglass cloth & epoxy which I faired with thickened epoxy and created a “knife-edge” trailing edge. I always thought the later Blanchards were stern heavy. So, this helped that. At the same time I took the keel to a foundry and had for 2″ hols bored in the top of the back of the “bulb” to remove 100 pounds…. for the same reason. I also built a new mahogany rudder which I also covered with glass & epoxy and gave a “knive-edge” trailing edge. Very racy! I had built Star boats and new rudders was part of that work so I had good skills for both the keel and hull work (since Blanchard used the exact same keels & rudders). When the boat was lowered onto the keel I sandwiched 3 layers of glass & epoxy between the hull and the top of the keel flange which made a good seal and “seat” there. I also rebuilt the skeg and replaced the bolts with stainless (threaded rod) and stainless pintles & gudgeons (the “hinges). The keel & rudder are painted white so I can tell if they are clean when I scrub the bottom before races.

The boat sits on a custom made (for $8000) trailer with keel-guides so it can be launched and hauled on a normal boat launch ramp.

Mast & boom refinishing

All the spreaders, rigging, and other hardware were removed from the mast to refinish it with multiple coats of Interlux Gloss White. Bronze fittings were sandblasted and sprayed with clear polyurethane. Two pictures show the boom which I rebuilt new with 7 laminations of Sitka spruce (or maybe it was Port Orford cedar) with a layer of glass cloth & epoxy in each lamination ( a couple decades earlier) and the rebuilt V-spreaders (3 laminations, spruce, as I recall, with glass & epoxy in each lamination), then the outside wrapped in glass cloth & epoxy.

Opening Day Fun on B73 – circa 1987